Principle of glass soldering by ultrasonic technology

How is it possible to solder on glass or ceramics?

By using special solder alloy Cerasolzer and the ultrasonic soldering device Sunbonder, it’s possible to solder on substrates that have previosuly been deemed unsolderable. We will now explain the reason behind it.

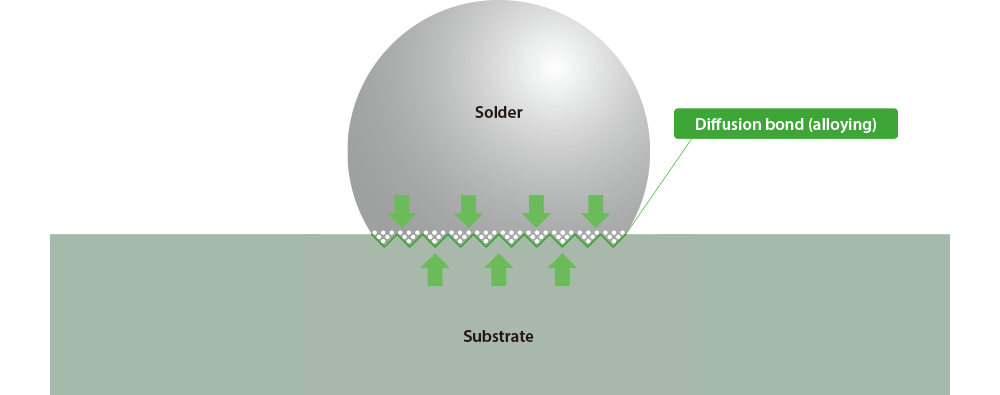

Old generation soldering technique

In the past, soldering was being done by heating the solder over its melting point to create a bond between it and the metal substrate.

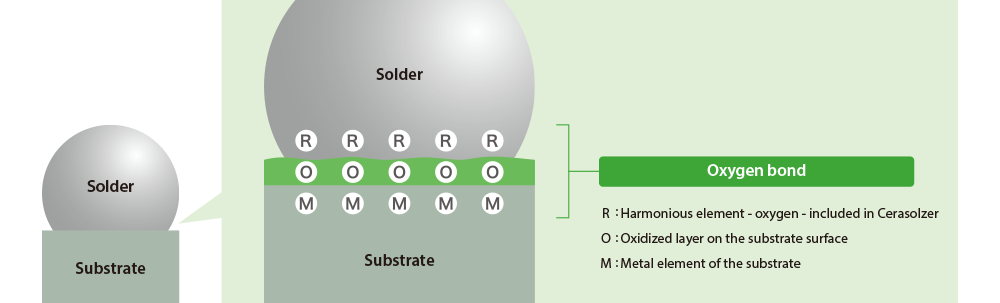

Creating a bond with Cerasolzer / Cerasolzer Eco

Thanks to Komura-Tech’s special solder, Cerasolzer / Cerasolzer Eco, you can now bond previously unsolderable materials, such as glass and ceramics.

Cerasolzer includes elements which have a very strong chemical affinity with oxygen, as a result of which a bond with the oxidized layer on the substrate surface is easily created.

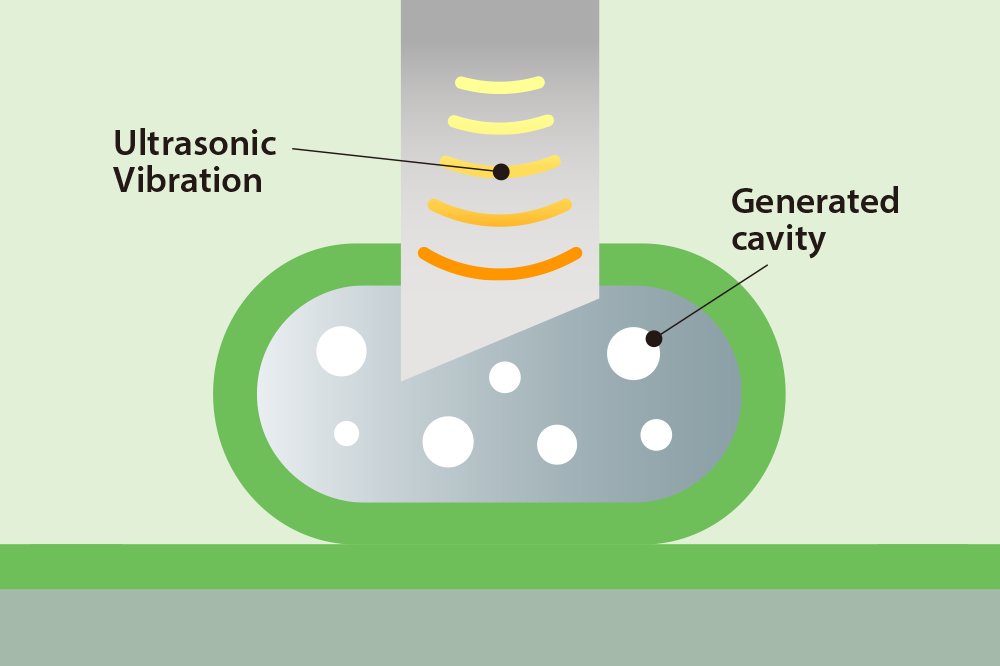

Sunbonder cavitation effect

By using ultrasonic soldering device Sunbonder, a cavitation effect occurs.

By means of ultrasonic soldering, the air particles within the solder rupture, and the shockwave raised at that moment dissolves any oxidations, dirt, resin particles etc. on the surface of substrate, enabling the creation of a more stable and reliable bond. Ultrasonic soldering facilitates diffusion and oxidation.

In a word, Sunbonder enables non-flux soldering.

Thus, Cerasolzer and Sunbonder made soldering on glass, ceramics, tungsten, molybdenum, titanium, nitrides and carbides possible, all thanks to the bond created with an oxidated layer on the substrate surface.

Our company enables soldering things that were deemed unsolderable before.

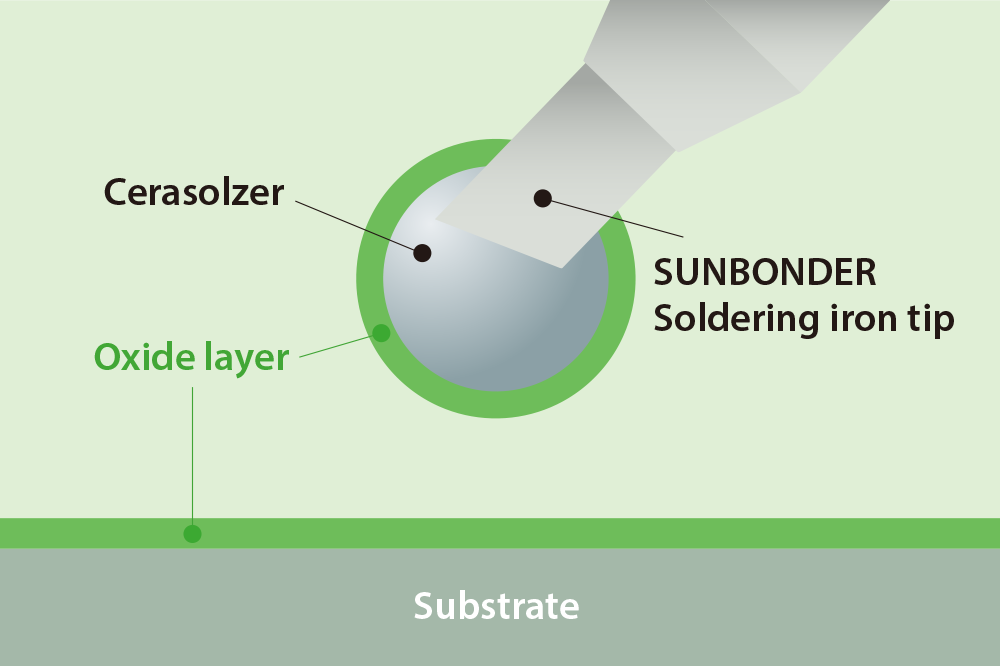

(1)Solder gathered on the soldering tip

Both the solder and the substrate are covered in oxidation. The substrate is covered with dust particles and dirt.

(2)Solder being placed on the substrate

Oxidized layer still presents on the solder and the substrate.

(3)Ultrasonic are being released

The cavity is generated in the melted solder material during generating negative pressure by ultrasonic vibration.

By cavitation effect, the oxidation at the point of contact disappears.

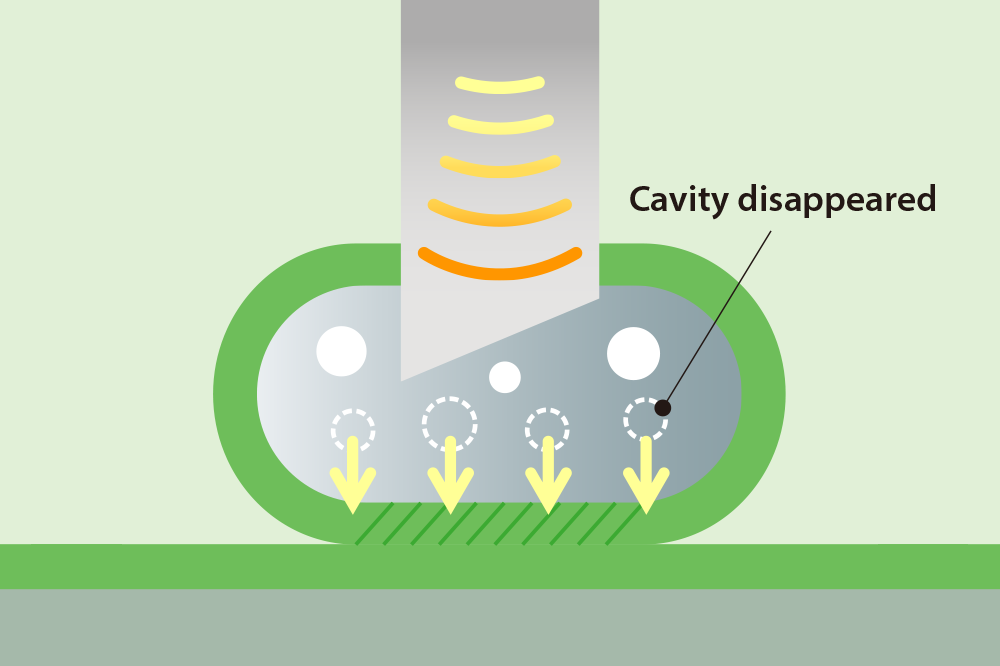

(4)Cavity is disappeared.

The cavity is disappeared during generating positive pressure by ultrasonic vibration. Then the oxide layer on the substrate is impacted.

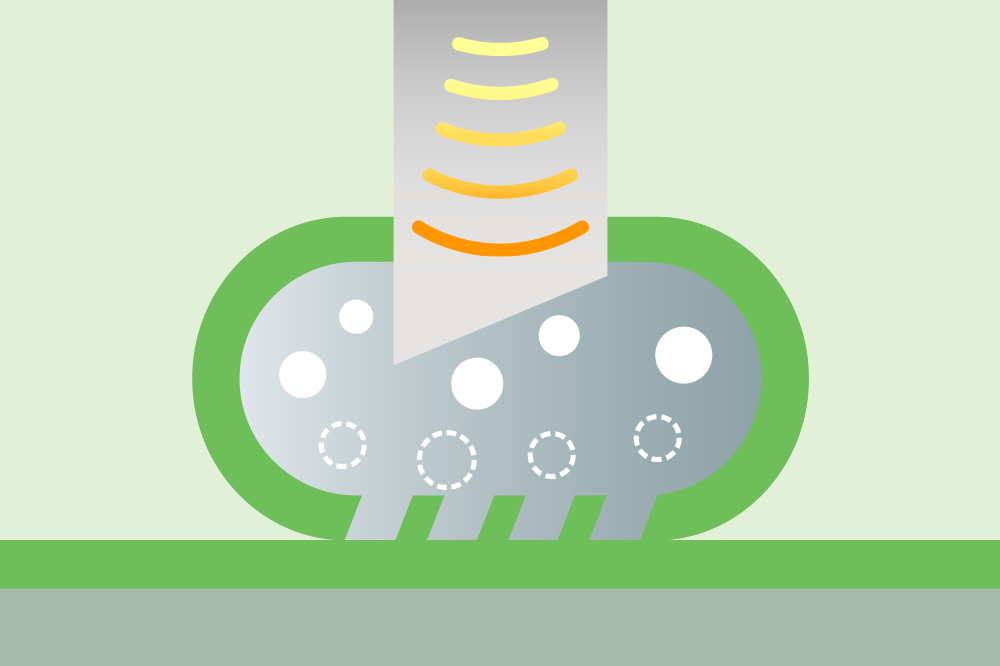

(5)Oxide layer around melted solder material is removed

By cavitation effect, the oxidation at the point of contact disappears.

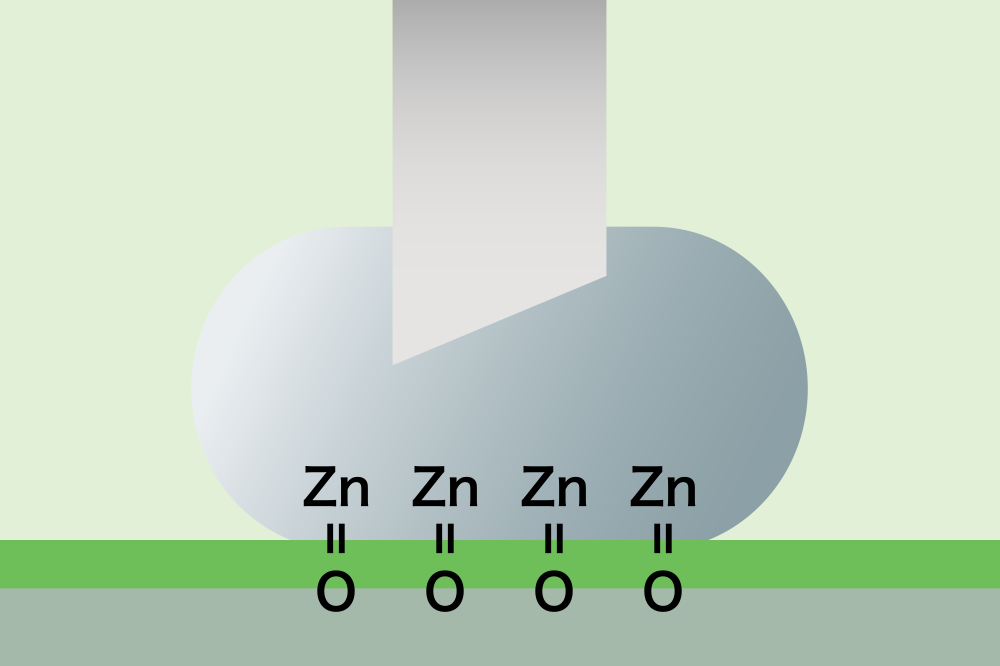

(6)Composition in solder bond to the substrate

Zinc in solder and substrate have been bonded by oxygen.

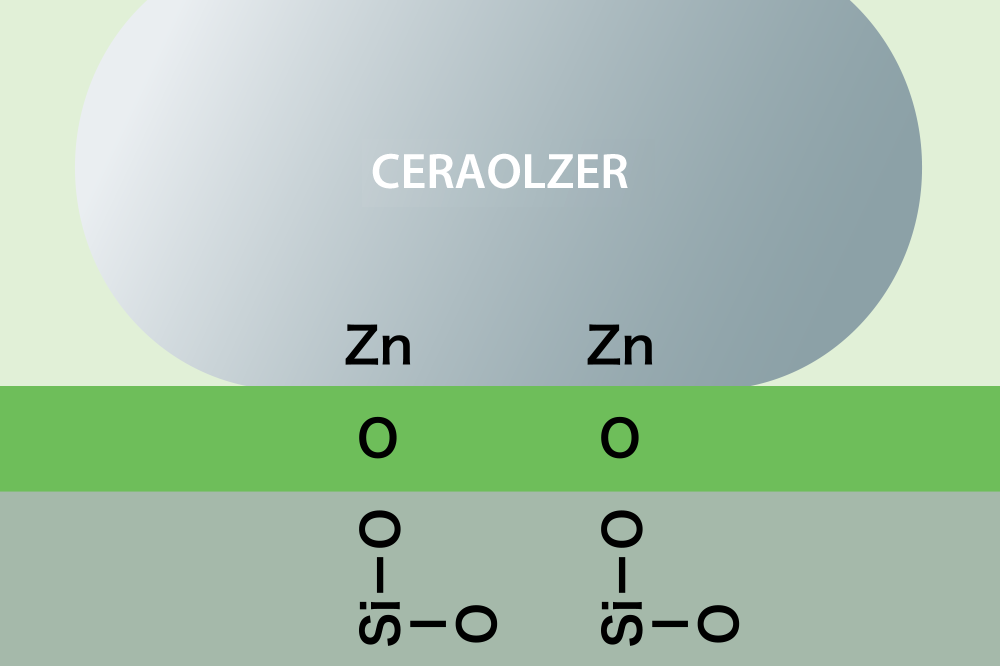

(7)Glass and CERASOLZER have been bonded

The oxide layer on glass (SiO2) and CERASOLZER have been bonded at the both surfaces.

c KOMURA-TECH CO.,LTD. ALL RIGHTS RESERVED.

+81-45-590-0078