Ultrasonic soldering iron SUNBONDER USM-560/USM-540/USM-528

Introduction

Sunbonder is your best choice for flux free, high quality ultrasonic soldering.

Traditional soldering uses flex which requires cleaning process and causes pollution . Our innovational ultrasonic soldering technology eliminates flux, Sunbonder introduces a new soldering experience.

Accompanying with our special solder, Cerasolzer, you can solder almost everything. Our products performs perfectly from glass to molybdenum except organic substances.

Characteristics

Flux

freeProvides flux-free soldering. No cleaning process required and no concern of residues.

Bonding

to

low-solderability

materialsEasy to solder on low-solderability materials like glass, ceramic and aluminum.

Rohs

complianceUSM-560 and USM-540 are RoHS compliant products. (*USM-528 is not compliant.) Please click here to see the non-use certificate.

Source

voltage

for

oversea useCompatible with AC100V-240V for use overseas. We will ask your desired power supply voltage at the time of order and adjust it before shipment.

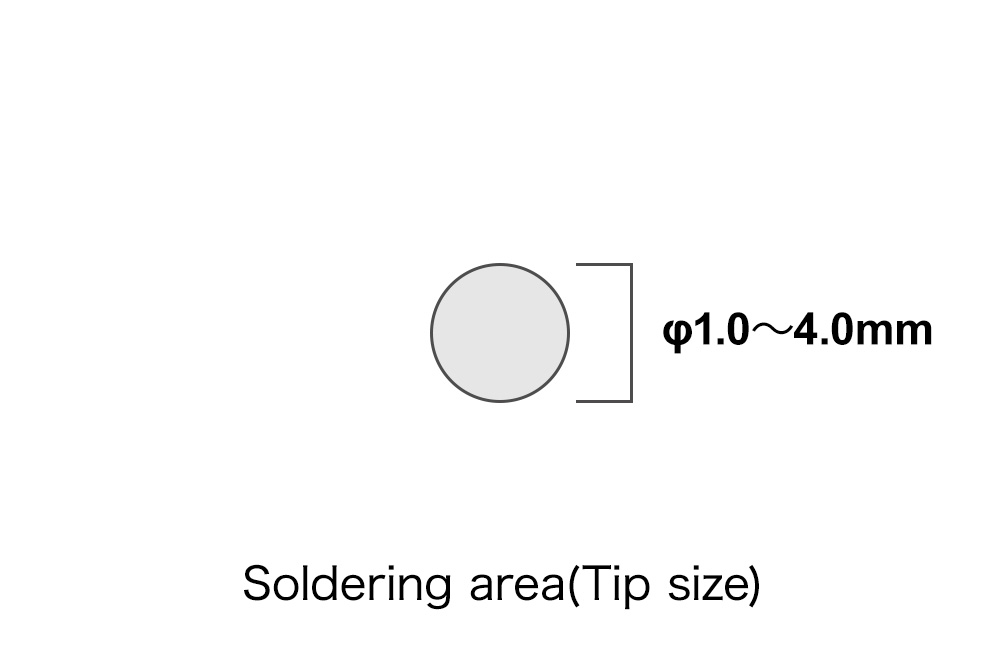

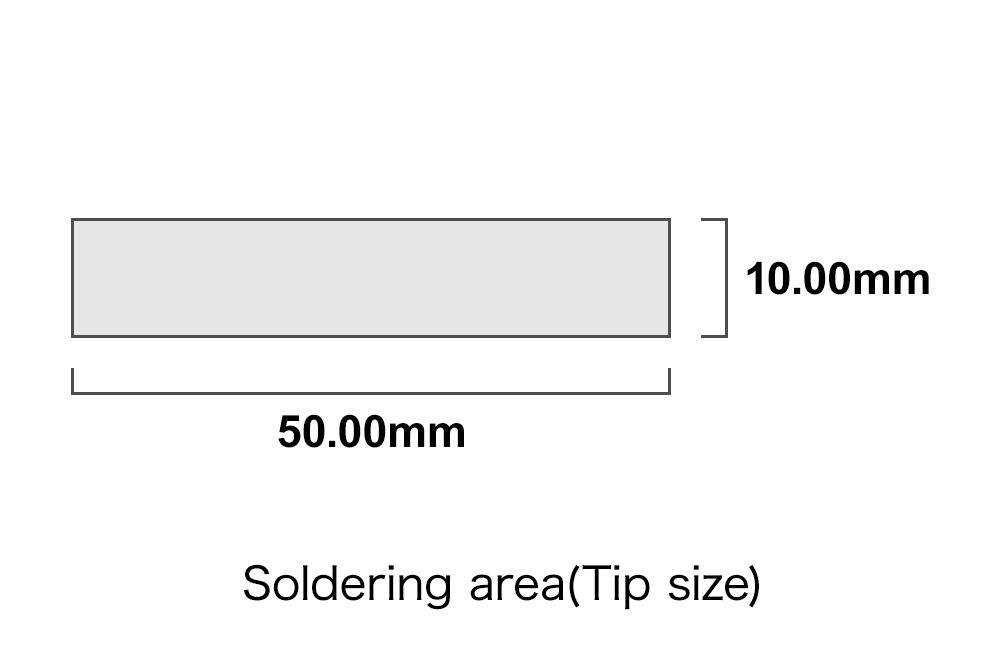

Solderable area (tip diameter)

The USM-series has three types, each with a different solderable area (tip diameter).

This product solves these problems

Case (1) Soldering aluminum

| Before adoption | Soldering with strong acid flux to remove the aluminum oxide film. Flux cleaning was required |

|---|---|

| After adoption | Ultrasonic soldering method is flux-free soldering, it shortened the manufacturing process. |

Case (2) Bonding target materials

| Before adoption | Soldering with strong acid flux to remove the aluminum oxide film. Flux cleaning was required |

|---|---|

| After adoption | Improved the variation and voids, and drastically reduced the loss of indium material. |

Case (3) Electrode wiring to solar cell glass

| Before adoption | Bonding with silver paste requires a drying process, and ACF (anisotropic conductive film) is expensive. |

|---|---|

| After adoption | Simplified mass production process and reduced the material cost. |

Solderable material

Compatible with low-solderability materials, such as glass, ceramic, stainless steel, and superconductor wire.

For details, please refer to “Solderable material list“.

Specification

| Model No. | USM-560 | USM-540 | USM-528 |

|---|---|---|---|

| Standard price (Generator+a set of iron) |

Please refer to “Price information“ | ||

| Tip size | φ1.0~4.0mm | φ10.0mm | 50mmx10mm |

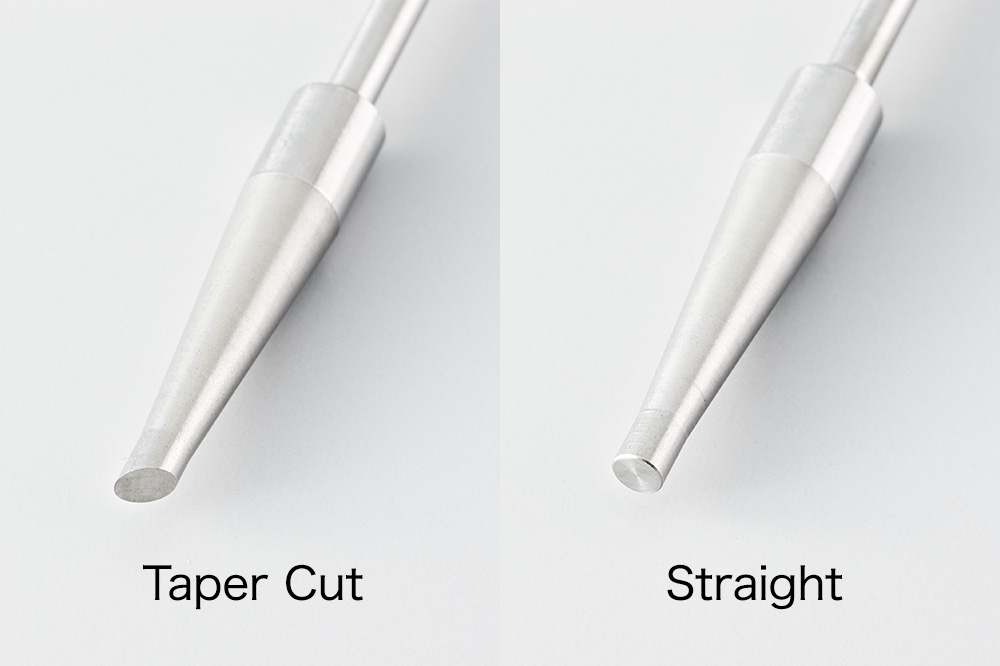

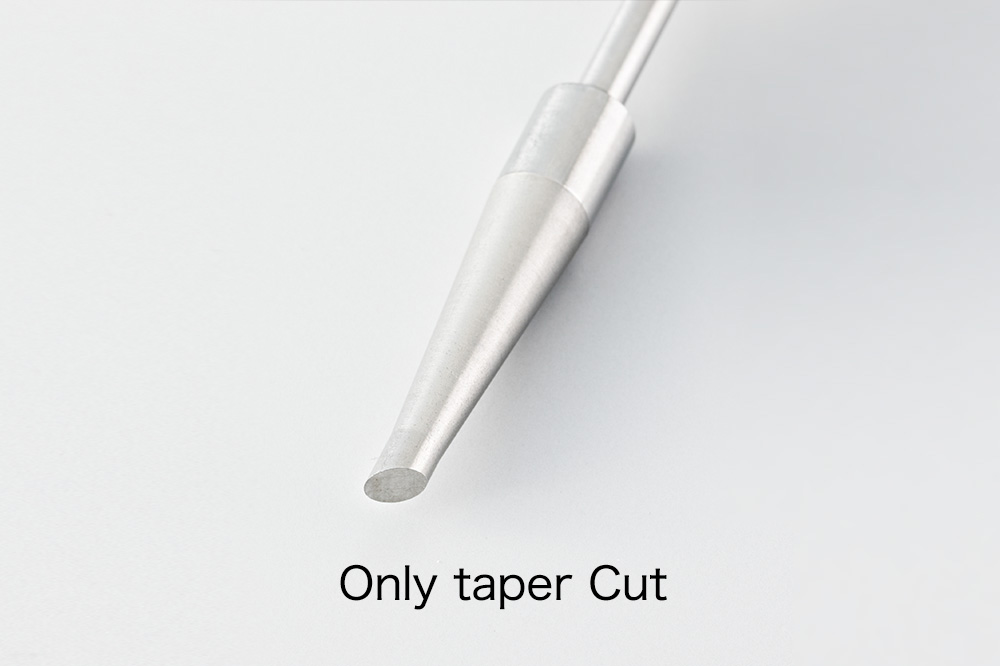

| Tip end shape | |||

| Generator size | 21×23.5×9cm | 21×23.5×9cm | 26×32×14cm |

| Generator weight | 5kg | 5kg | 10kg |

| Packing Dimensions | 41×36×22cm | 41×36×22cm | 60×41×39cm |

| Gross weight | 7.9kg | 8.0kg | 15.0kg |

| Ultrasonic frequency | 60kHz | 40kHz | 28kHz |

| Replaced model | USM-Ⅲ/USM-Ⅳ | SO-6 | USM-28 |

| Max temp | 500℃ | 600℃ | 350℃ |

| Ultrasonic power(max) | 12W | 12W(at no load) 20W(when soldering) |

12W(at no load) 70W(when soldering) |

| Power | 100~240V | 100~240V | 100~240V |

| CE mark | ○ | ○ | × |

| Instruction manual | Download(PDF) | Download(PDF) | Download(PDF) |

Product catalog

From agreement to delivery: flow

Delivery takes approximately 2 weeks after receipt of the order.

![]()

1.Inquiry

![]()

2.Meeting

![]()

3.Proposal and quotation

![]()

4.Order and submission of specification confirmation sheet

![]()

5.Shipment in approximately 2 weeks

Contact us

+81-45-590-0078

Komura-Tech Co., Ltd.

c KOMURA-TECH CO.,LTD. ALL RIGHTS RESERVED.

+81-45-590-0078