Special Solder CERASOLZER

Introduction

Special Solder Cerasolza is the world’s first special solder that can attach to glass.

We provide both Cerasolzer Eco (Pb-free) and a Cerasolzer (Pb-based).

The Cerasolzer series features a special formula and ultrasonic soldering technology that achieve perfect bonding to glass and ceramics.

(*Ultrasonic soldering requires our ultrasonic soldering machine, Sunbonder.)

It achieves bonding to low-solderability materials, such as glass, ceramic substrates,aluminum, tungsten, molybdenum and titanium.

In addition, the cavitation effect of ultrasonic waves activates the molten solder surface and removes the oxide film, flux is not required.

- No need for any pre-treatment (vapor deposition or heating) to the substrate surface.

- Ultrasonic soldering uses cavitation phenomenom instead of chemical agent (flux).

- Suitable for bonding almost all “low-solderability” materials.

- Preventing voids.

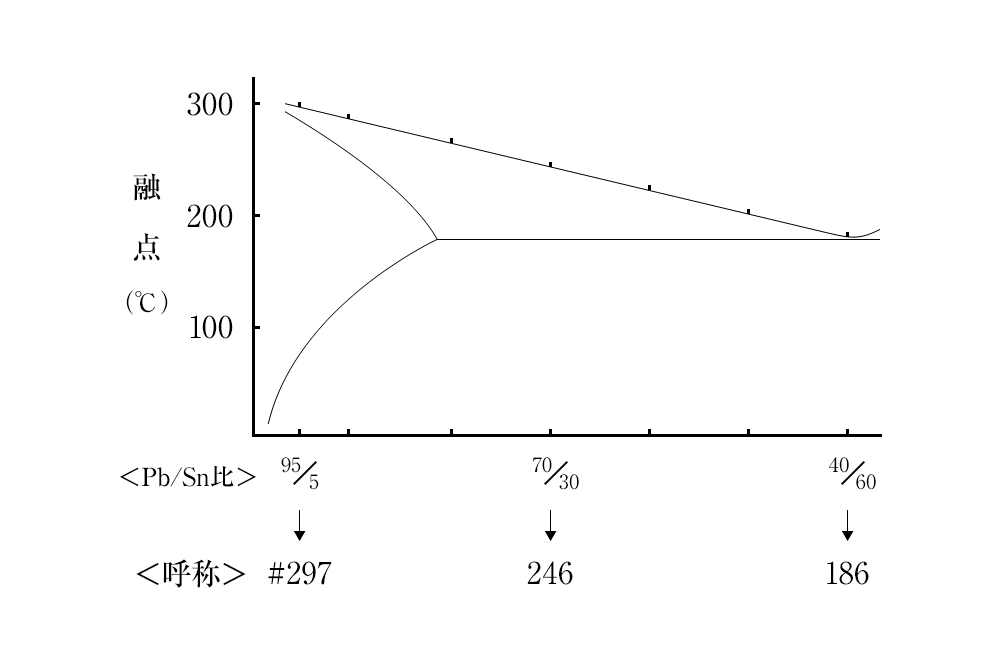

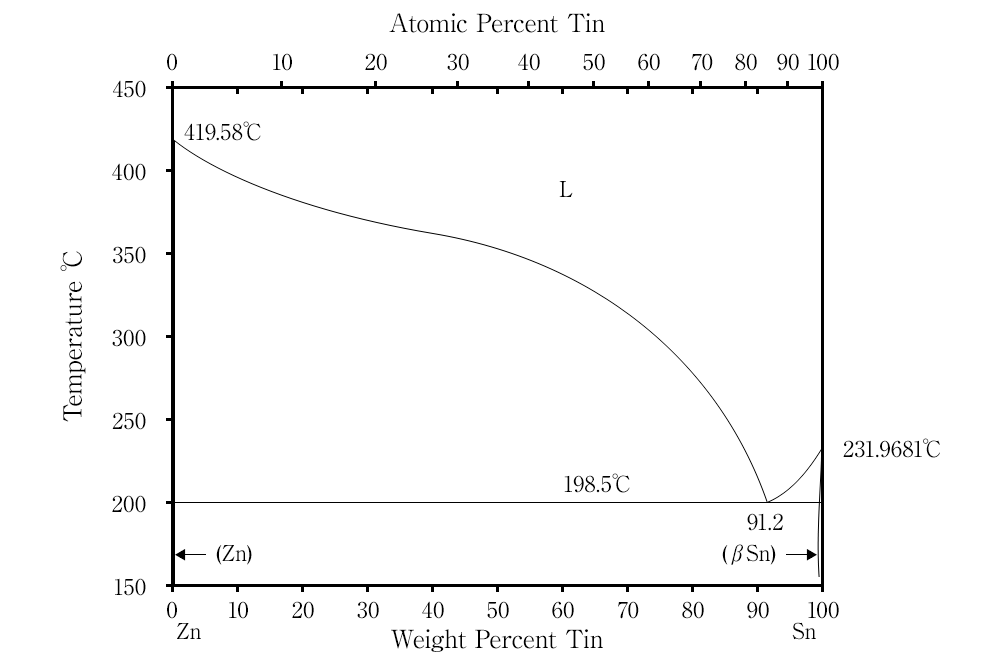

- Different solder melting points are available from 155°C to 297 °C.

Fig.1 Pb-Sn system phase diagram, melting point and model no. of Cerasolzer.

Fig.2 Sn-Zn system phase diagram, melting point and model no. of Cerasolzer.

Characteristics

Glass-ceramics

bondingWe have made it possible to bond materials that were once thought to be impossible to solder.

Soldering

stainless

steelStainless steel can be bonded as if it were a normal soldering process. No welding or other qualifications are required.

Soldering

superconducting

wireWe have made it possible to solder to superconducting wires such as niobium-titanium alloys used in MRI and linear motors.

This product solves these problems

Case (1) Soldering aluminum

| Before adoption | Bonding with silver paste requires a drying process, and ACF (anisotropic conductive film) is expensive. |

|---|---|

| After adoption | Simplified mass production process and reduced the material cost. |

Case (2) Fixing prism

| Before adoption | Adhesives have been used to fix prisms in single-lens reflex cameras. Yet, there was a problem that the prism moves due to shrinkage when the adhesive is cured . In addition, adhesives deteriorate over time, making it difficult to guarantee long-term quality. |

|---|---|

| After adoption | By using a special solder Cerasolzer, stable fixing can be done quickly, and the absence of organic materials makes it possible to guarantee long-term quality. |

Case (3) Bonding Fiber Optic Ferrules

| Before adoption | Fixed by adhesion. Environmental resistance is a concern due to aging. |

|---|---|

| After adoption | Strong fixation, not affected by aging. |

Case (4) Soldering superconducting wires for MRI

| Before adoption | Cannot solder. |

|---|---|

| After adoption | Ultrasonic soldering made soldering possible. |

Solderable material

Compatible with low-solderability materials, such as glass, ceramic, stainless steel, and superconductor wire.

For details, please refer to “Solderable material list“.

Cerasolzer product line up

| Model | Melting point | Wire diameter | Unit | Standard price(Tax excluded) | Remarks |

|---|---|---|---|---|---|

| Cerasolzer#186 | 186℃ | 1.6φ | 150g | JPY8,000(Tax excluded) | Pb-based |

| Cerasolzer#186 | 186℃ | 1.0φ | 1Kg | JPY30,700(Tax excluded) | Pb-based |

| Cerasolzer#186 | 186℃ | 1.6φ | 1Kg | JPY30,700(Tax excluded) | Pb-based |

| Cerasolzer#297 | 297℃ | 1.6φ | 150g | JPY6,700(Tax excluded) | Pb-based |

| Cerasolzer Eco#155 | 155℃ | 1.0φ | 150g | JPY37,300(Tax excluded) | Pb-free |

| Cerasolzer Eco#182 | 182℃ | 1.0φ | 150g | JPY28,000(Tax excluded) | Pb-free |

| Cerasolzer Eco#217 | 217℃ | 1.0φ | 1Kg | JPY34,700(Tax excluded) | Pb-free |

Product catalog

From agreement to delivery: flow

Delivery takes approximately 5 days after receipt of the order.

![]()

1.Inquiry

![]()

2.Proposal and quotation

![]()

3.Order

![]()

4.Shipment in approximately 5 days

Contact us

+81-45-590-0078

Komura-Tech Co., Ltd.

c KOMURA-TECH CO.,LTD. ALL RIGHTS RESERVED.

+81-45-590-0078