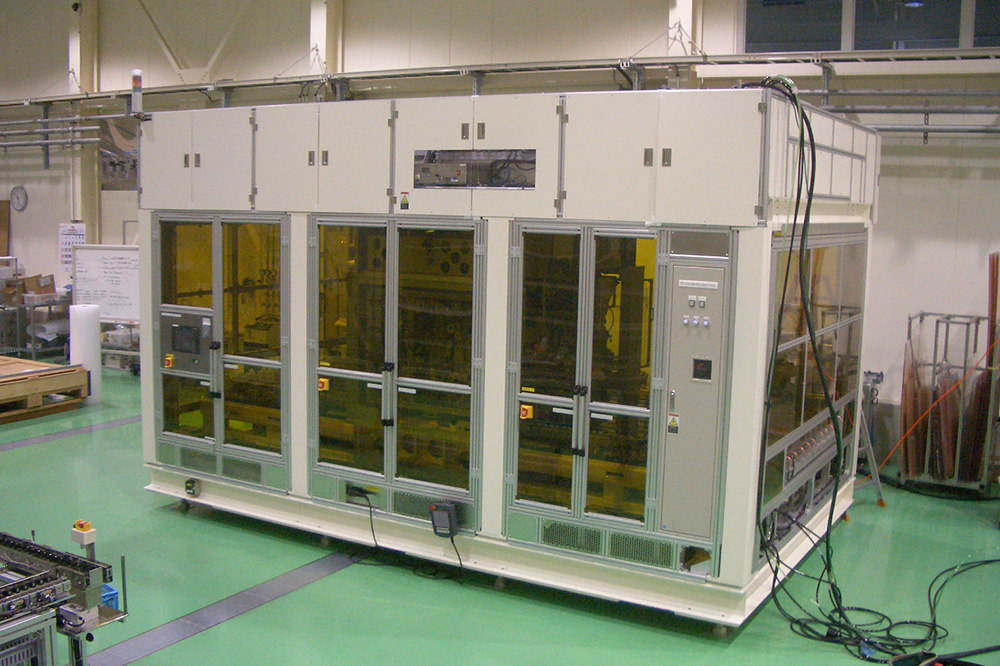

Ultrasonic Line Soldering and ribbon bonding tool USK-Line-5000/8500

Introduction

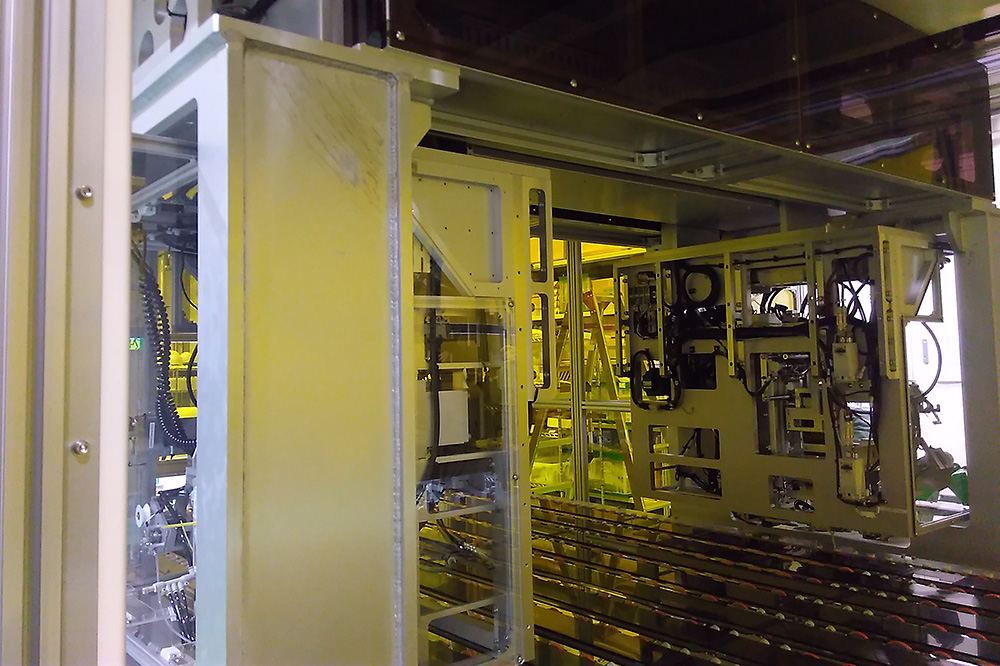

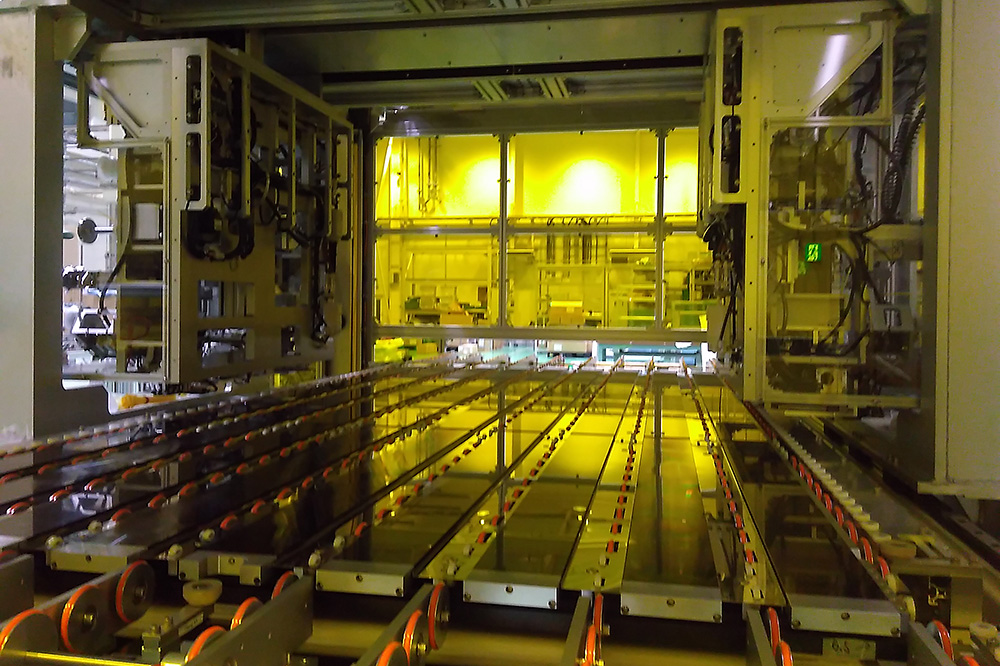

This equipment is for bonding electrodes to glass substrates for solar cells, light dimming glass, organic EL, etc.

Glass soldering is impossible, but with our ultrasonic soldering technology, soldering on glass surface is easy and perfect.

By bonding copper flat wires coated with a special solder to the soldered position, it becomes electrode wiring for extracting charge from solar cells and for applying voltage to dimming glass, etc.

Characteristics

CERASOLZER

World’s only alloy enabling soldering to glass.

SUNBONDER

Compact ultrasonic soldering device that can remove oxide film without flux.

CERARIBBON

Electrode wiring coated with CERASOLZER, which has good bonding compatibility with pre-soldering by CERASOLZER.

Labeler

Supplying tape to fix electrodes to the junction box on the back of the solar cell.

Automation

technologyApplying HDD assembly automation technology, which we have been developed over 40 years, to ultrasonic soldering.

Bonding

processWe provide one stop solution for all the technologies of materials, ultrasonic sound, automation equipment.

This product solves these problems

When problems occur during mass production, such as electrodes not sticking, it is necessary to identify whether the material, ultrasonic sound, mounted equipment, or facilities are at fault, and then request multiple manufacturers to investigate the problem.

Since we perform everything from development / manufacturing to repair / maintenance in-house, there is no need for customers to isolate defects or contact multiple manufacturers.

Results and experience

| Solar cell electrode wiring | Used as electrode wiring with no deterioration even in harsh environments. (Dynamic glass・dimming glass electrode wiring) |

|---|---|

| In-vehicle ITO glass electrode wiring | For aspheric glass, we use articulated robots to wire electrodes. |

| Cosmetic tape application | Developable as a tape applicator using 5×10 size glass substrate transfer and XYZ mechanism |

Specification

Ultrasonic Line Soldering and Ribbon Bonding for Dynamic Glass

USK-Line-5000

| Application | Dynamic glass (dimming glass) |

|---|---|

| Overview | On ITO film glass substrate, ultrasonic line soldering the solder for electrode in 3mm width, then bonding copper flat wire over the solder. |

| Workpiece | ITO film glass substrate 3,000mm x 1,500mm x t0.5mm |

| Ultrasonic wave | 40kHz/60kHz |

| Soldering material | CERASOLZER ECO 217 (Pb-free, melting point 217℃) |

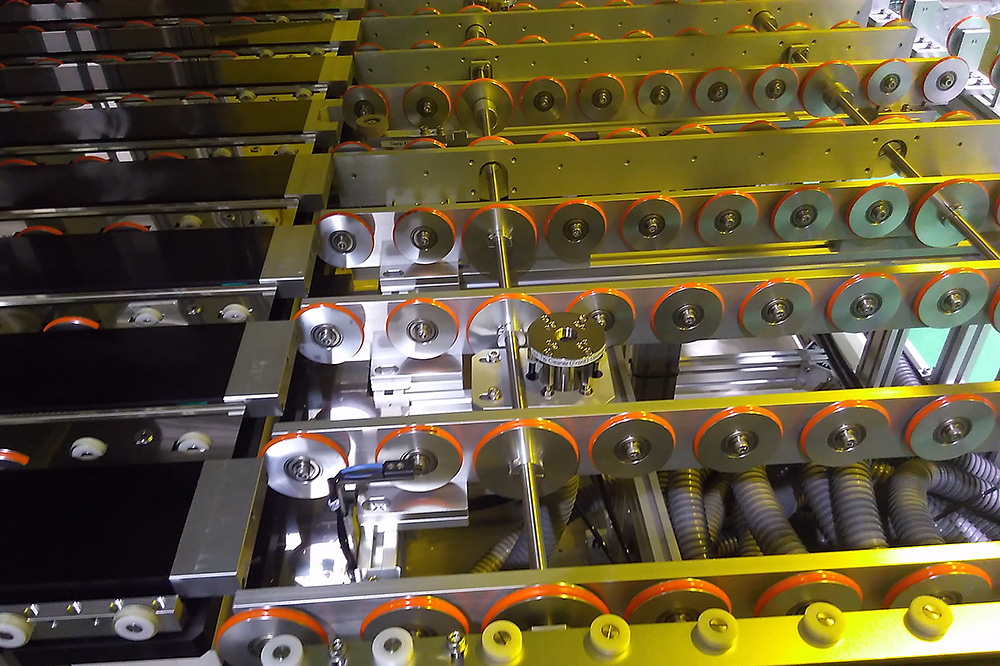

| Characteristics | Can transfer thin, large-area glass and reduce wiring thickness to 200 μm or less. |

Ultrasonic Line Soldering and ribbon bonding tool for

PV USK-Line-8500

| Application | CIGS electrode wiring |

|---|---|

| Overview | On CIGS film glass substrate, ultrasonic line soldering the solder for electrode in 3mm width, then bonding copper flat wire over the solder. |

| Workpiece | CIGS film glass substrate 1,200mm x 600mm |

| Ultrasonic wave | 40kHz |

| Soldering material | CERASOLZER ECO 217(Pb-free, melting point 217℃) |

| Characteristics | Stable tip end cleaning mechanism using round tips. |

From agreement to delivery: flow

Delivery takes approximately 2 to 9 months after receipt of order, depending on the volume of the device.

![]()

1.Inquiry (perform sample test, etc. as needed.)

![]()

2.Meeting (we will ask you what kind of equipment you need)

![]()

3.Proposal and quotation (proposal of process and equipment specification)

![]()

4.Order

![]()

5.Design, material arrangement, manufacturing, and adjustment

![]()

6.Onsite customer acceptance inspection and training.

![]()

7.Packing and shipping

![]()

8.Installation, adjustment, and flow operation confirmation

Contact us

+81-45-590-0078

Komura-Tech Co., Ltd.

c KOMURA-TECH CO.,LTD. ALL RIGHTS RESERVED.

+81-45-590-0078